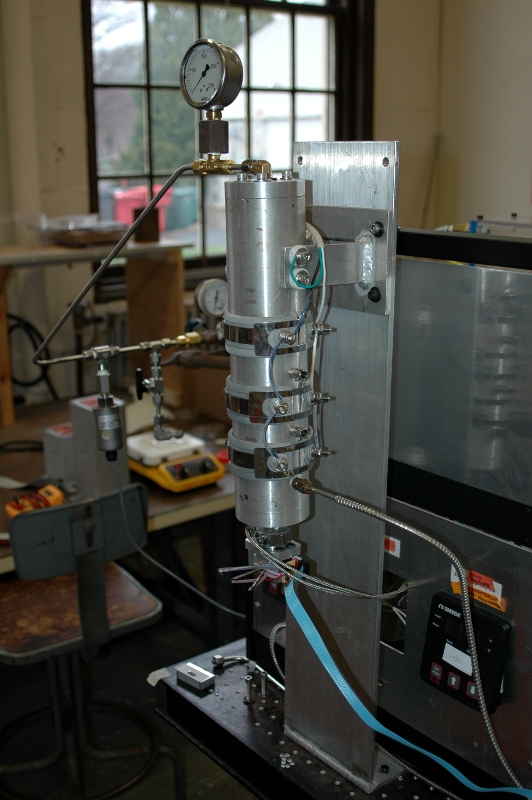

Experimental setup during first 2kPSI pressure test

Note Kevlar Helmet, Kevlar Vest, Stainless Steel Shield. Safety first (or at least top three)

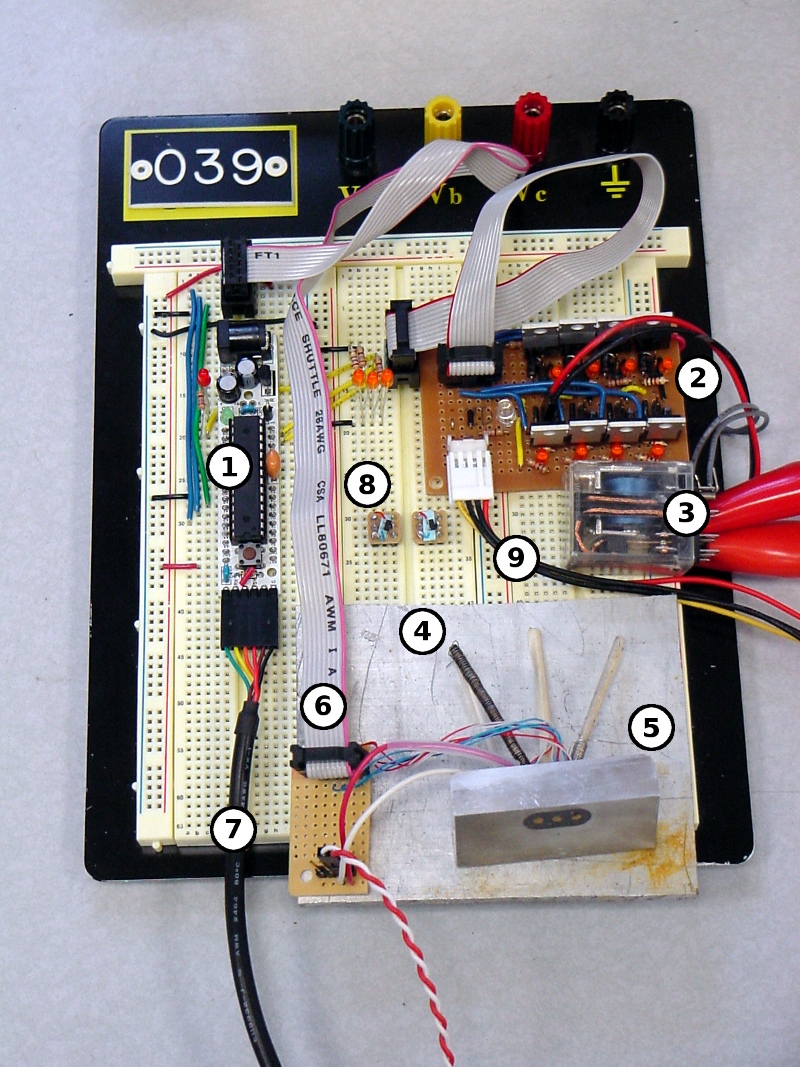

1) Arduino RBBB Running 3 ch PI controller

2) Relay interface board

3) 12 VDC Relay

4) 30 AWG Ni-Chrome Heater Coil

5) Test Heater Block

6) Temperature Feedback (from LM35 to Arduino ADC pins)

7) RS232 Data Connection

8) SOT23 LM35 Test adapter

9) Relay Board Power (molex standard 12v Gnd Gnd 5v )

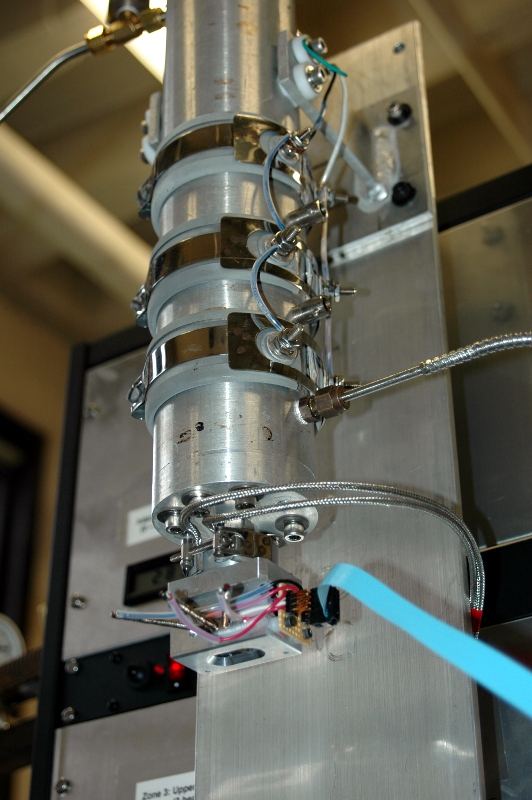

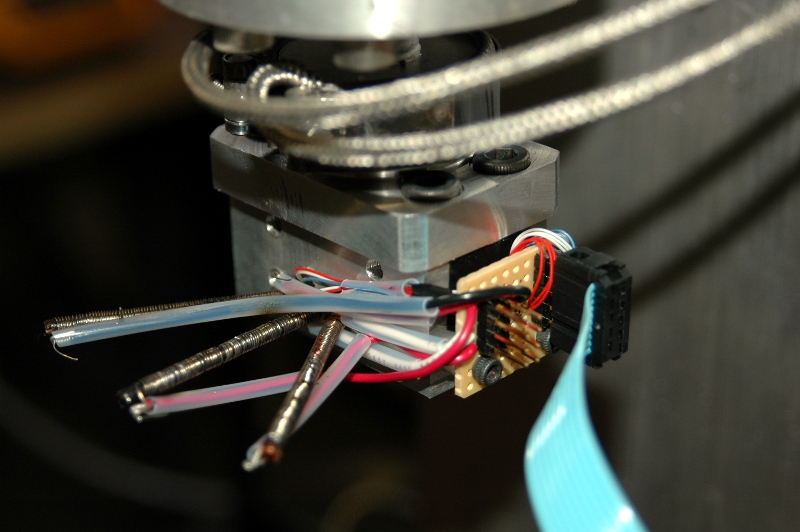

Blue ribbon cable connects to three embedded LM35s Red +5vdc White Gnd Blue Signal

Heavy conductor (connected to header) connects to 24vdc power supply

(Note all conductors shielded with teflon tube)

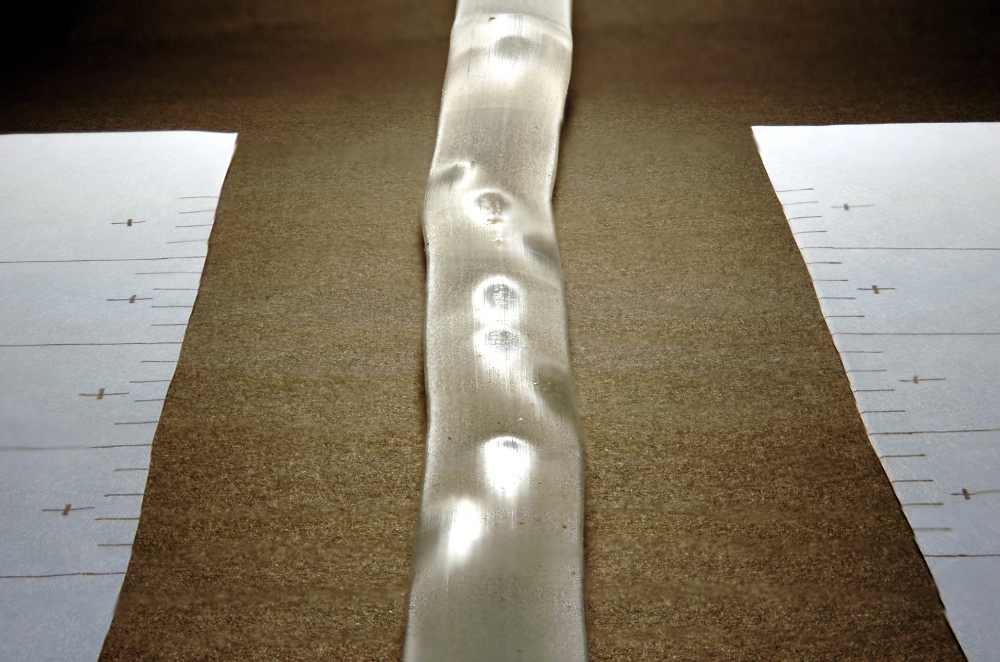

My 3 pixel font developed to utilize the 3 heater pins of my die head

(right click image to save true type font)

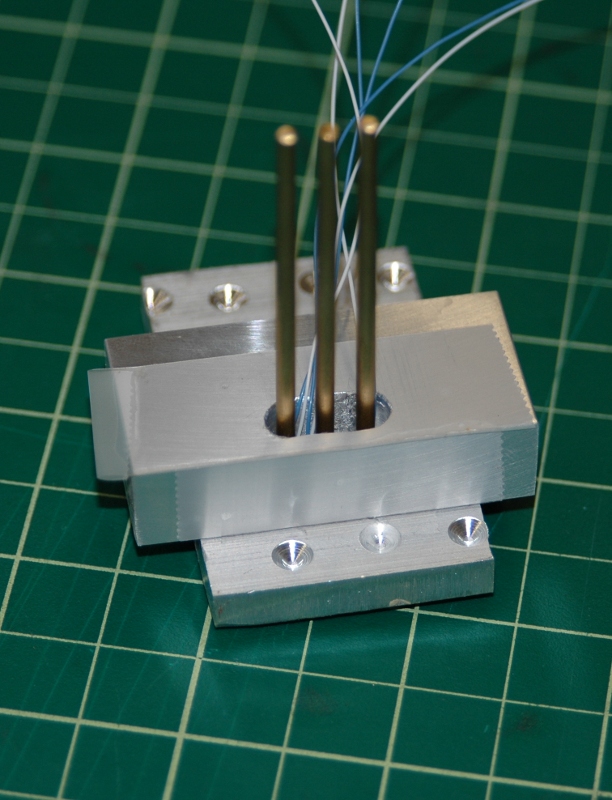

Heater Pins are aligned by using a specificly machined jig block.

(Note scotch tape over surfaces to aid in removal of excess epoxy)

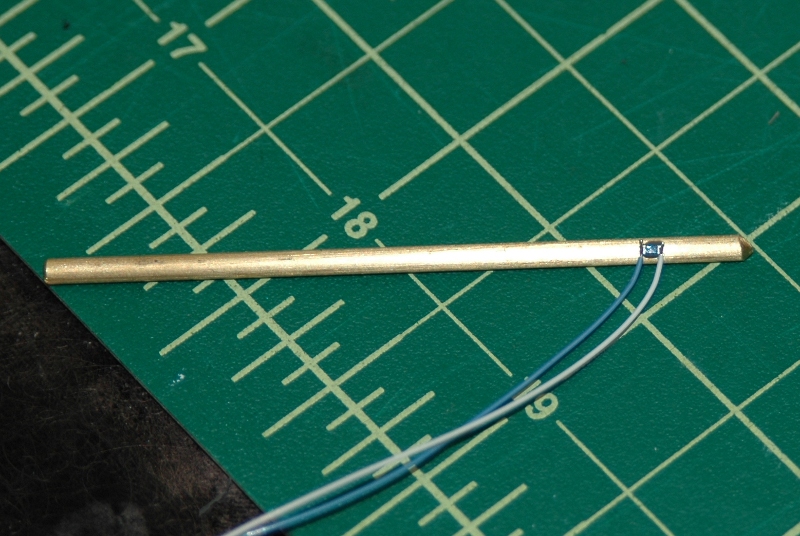

100 Ohm RTD affixed to heater pin

M printed open loop

Open loop extruder program. Designed to control heater coils connected to a PC parallel port. Executable and C++ source included.

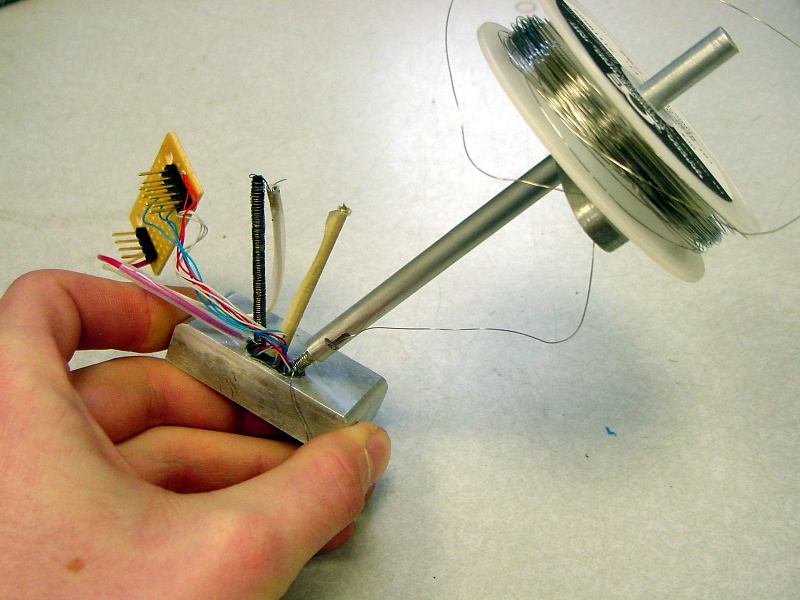

Method for winding 30AWG Ni-Chrome coils